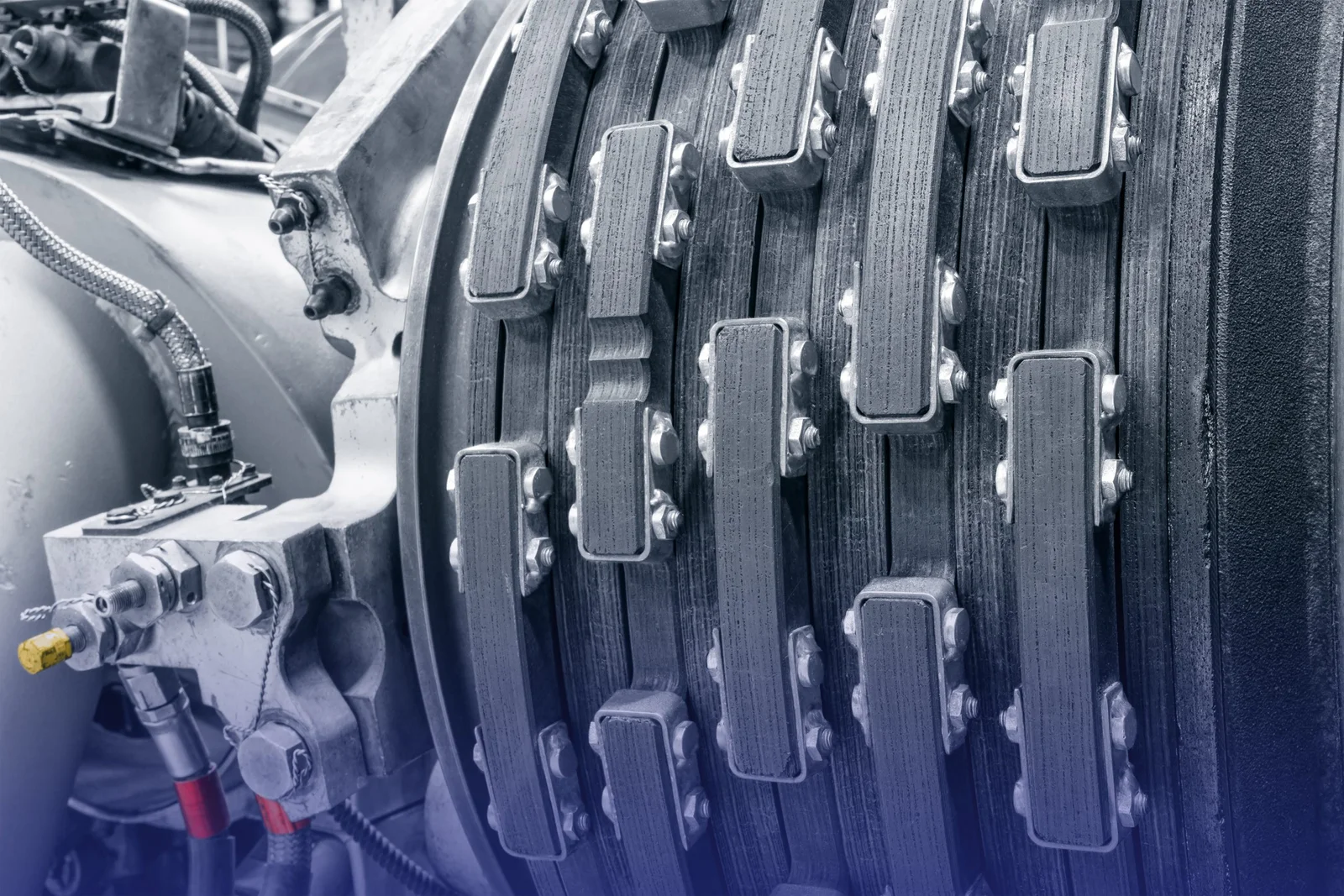

James Farnsworth Engineering offers a comprehensive range of services to meet the needs of your fleet, including line maintenance and technical support. We are dedicated to maintaining high standards of quality, safety, and customer service in all our operations.

James Farnsworth Engineering’s extensive experience in maintenance, repair, and overhaul (MRO) has given us deep expertise, enabling us to deliver high-quality maintenance services while meeting critical dispatch reliability targets.

The James Farnsworth Engineering Team provides global, round-the-clock support to address any aircraft on the ground (AOG) issues, regardless of location. They have a presence on both the East and West coasts of the United States, as well as internationally. The team is equipped with the necessary tools, equipment, parts, and project management expertise to quickly get your aircraft back in the air.

The James Farnsworth Engineering team has expanded its ability to provide on-site support for aircraft that are grounded due to issues, now including major airframe repairs and aircraft recovery. This comprehensive service offers cost-effective solutions globally for major airframe projects, encompassing aerospace engineering, specialized equipment like aircraft support structures, and temporary hangar access.

James Farnsworth’s Engineering expertise has allowed the team to build a diverse set of skills that can be applied to various rapidly evolving product lines. Through a commitment to ongoing enhancement, our team has managed to reduce the time required to complete projects to just 6 days.

Our core capabilities include:

James Farnsworth Engineering’s Specialized Counseling Administrations covers the complete lifecycle of an flying resource inside the regions of airplane and motor specialized administration with numerous a long time of combined encounter. Our Group is trusted by carriers, lessors and speculators, airplane and engine manufacturers, and other MROs to supply specialized back arrangements to their supplemental and extraordinary venture prerequisites, so they can center on the center of their trade.

James Farnsworth Engineering’s group has the capability of sending groups on brief outstation back to guarantee armada unwavering quality and specialized surge support.

The team at James Farnsworth Engineering is capable of providing nose-to-tail campaigns and supporting both planned and ad hoc base maintenance requirements.

One Canada Square

Canary Wharf

London, E14 5AB

United Kingdom

Email: contact@jamesfarnsworthengineering.com

Tel: +44 208 040 3203

James Farnsworth Engineering are committed to providing you as an aircraft owner, or operator a One Stop Shop for all your aviation needs.

© James Farnsworth Engineering. All Rights Reserved.